AVAILABLE FUNCTION OF HEAVY MACHINERY

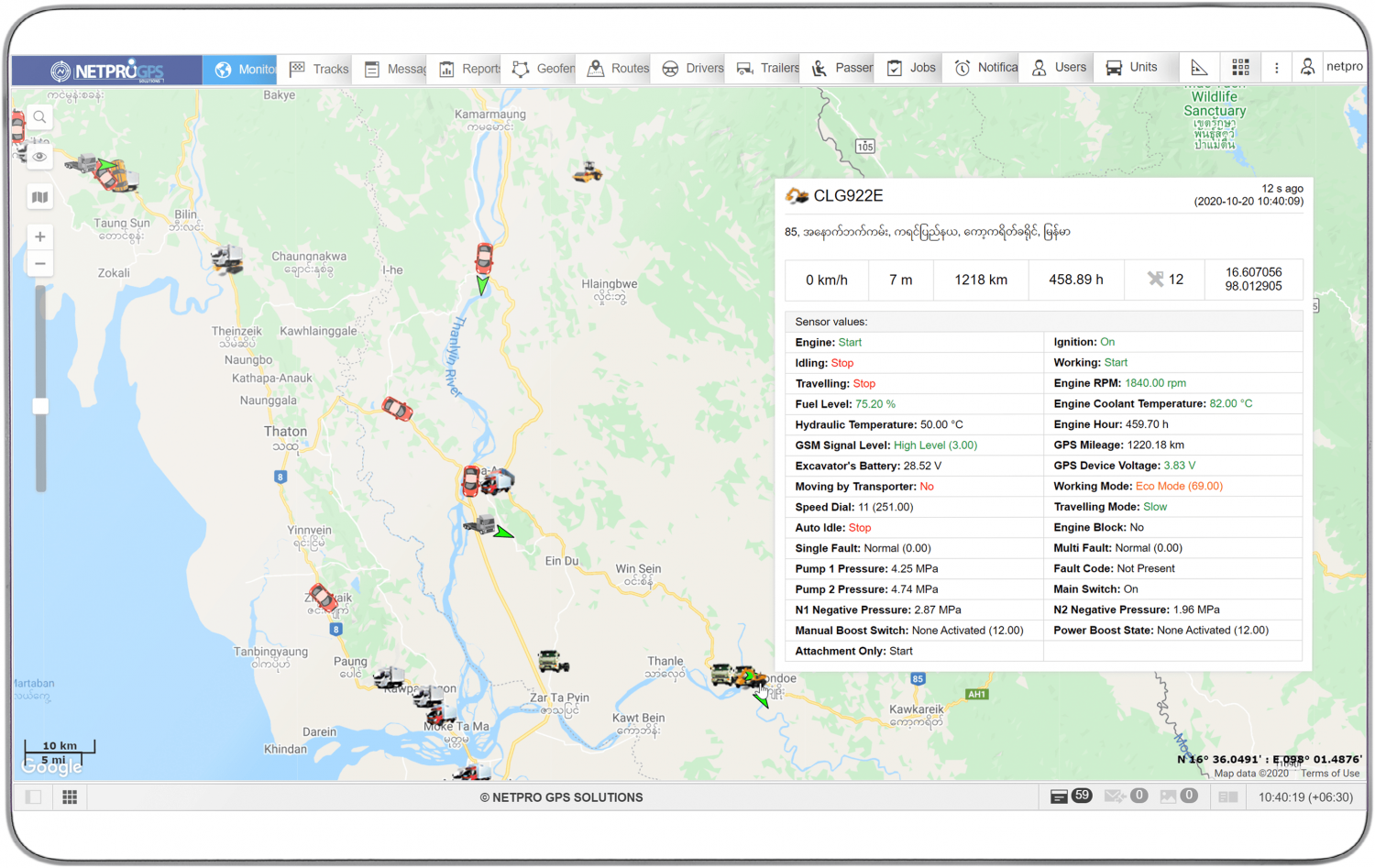

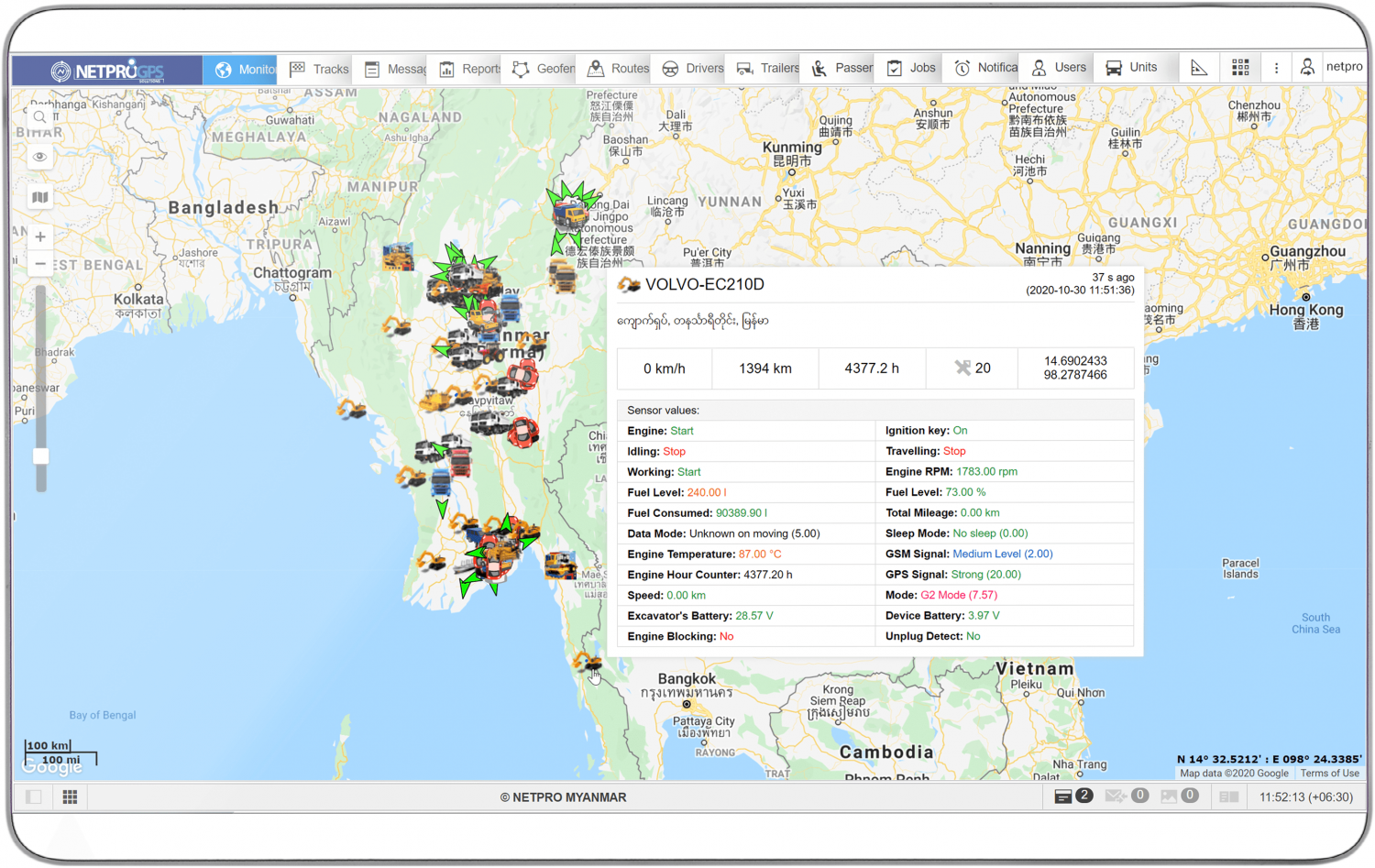

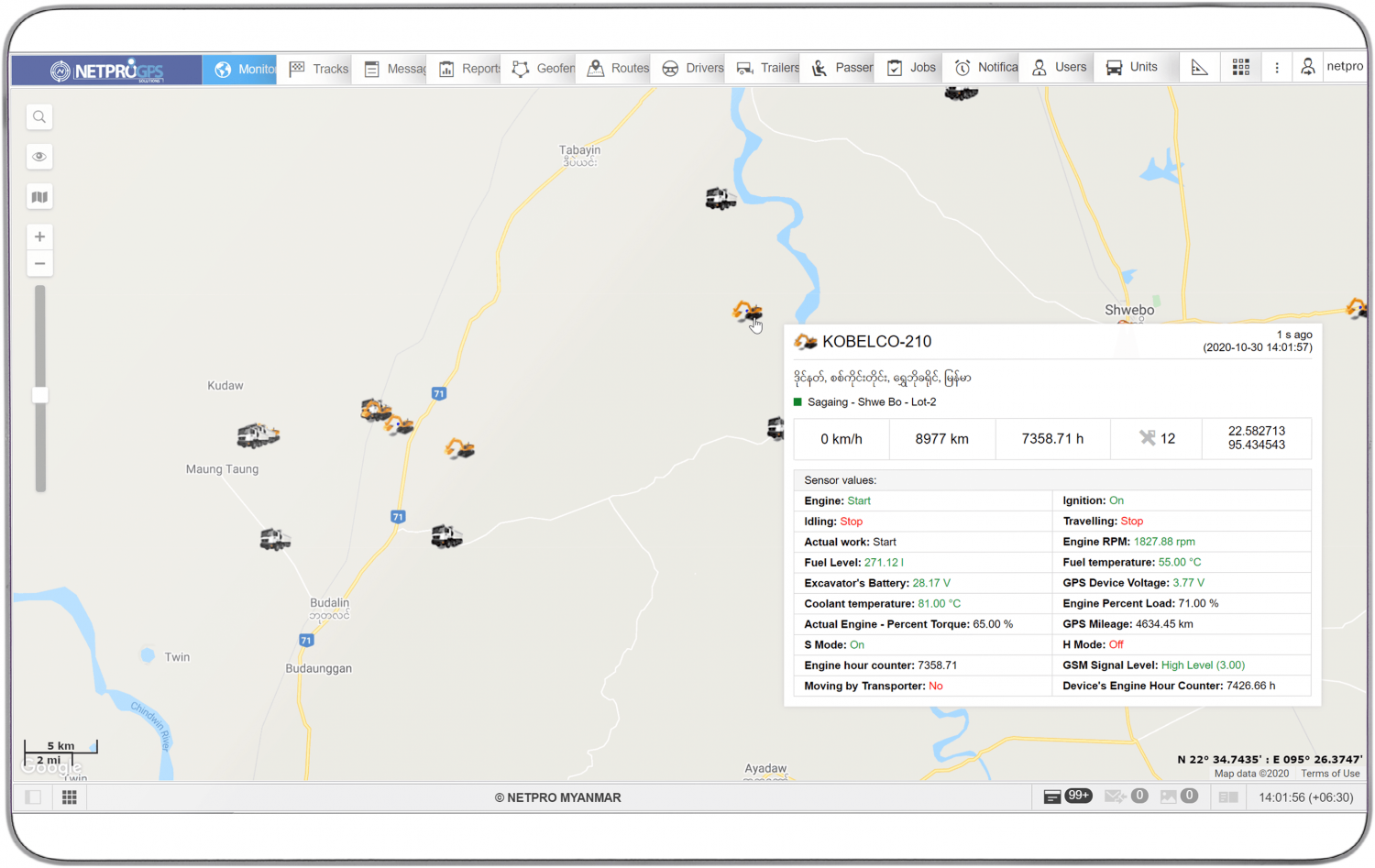

Engine Hour

Engine hour tracking is an important aspect of heavy equipment maintenance and operation. By accurately tracking the engine hours, construction companies can ensure that the equipment is being used efficiently and that regular maintenance is being performed. This helps to prevent costly breakdowns and prolongs the life of the equipment. Telematics and IoT devices provide an effective way to monitor and record engine hours, as the data can be easily accessed and analyzed remotely.

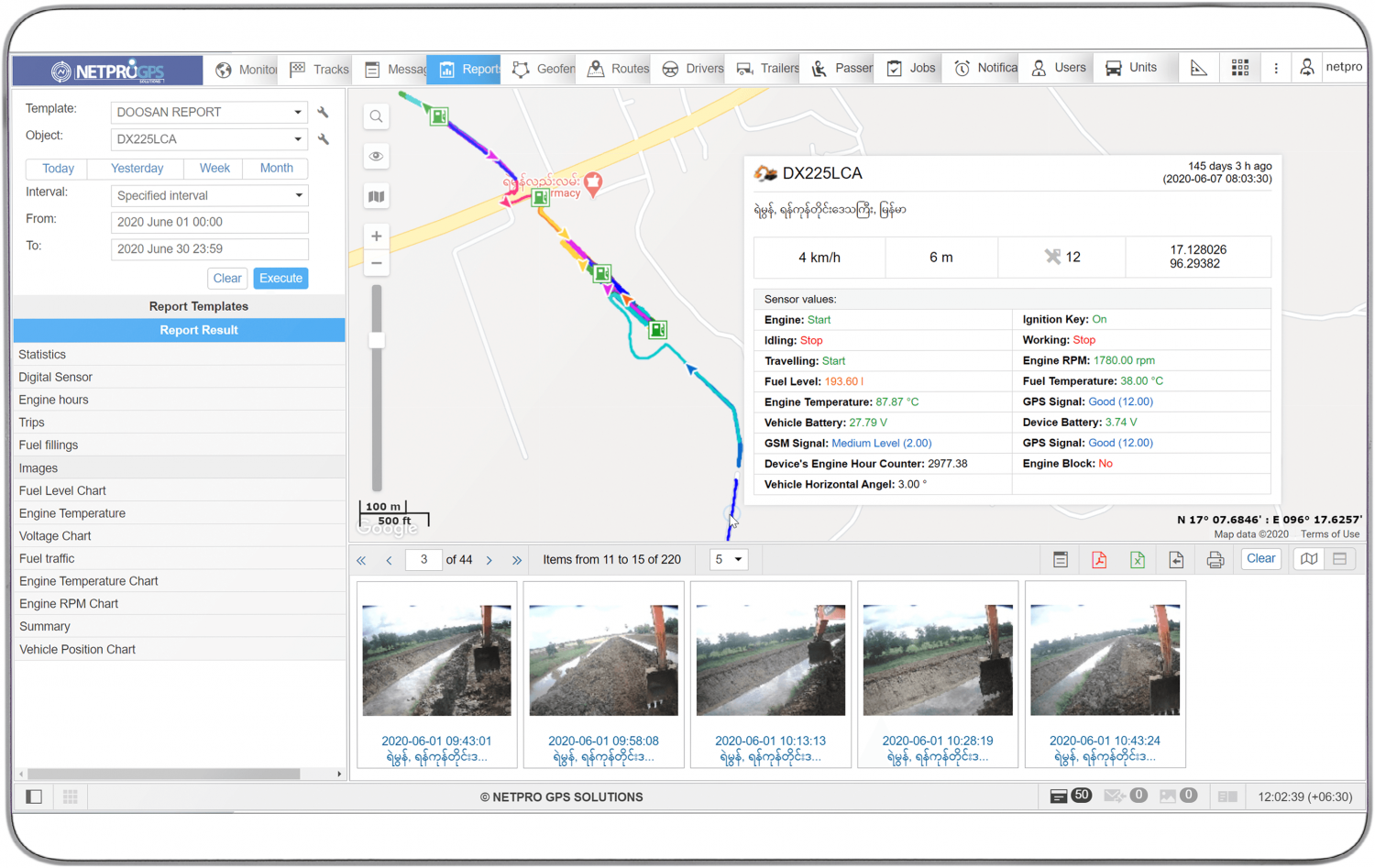

Working Hour

Our solution involves using technology to accurately track the engine hours of construction machinery rental equipment. This includes recording the total engine running hours, total working hours, total traveling hours, and total idling hours. These hours are calculated from the machine’s electronic control unit and cannot be easily manipulated. This helps to prevent cheating and increase productivity, fuel economy, and decrease maintenance costs.

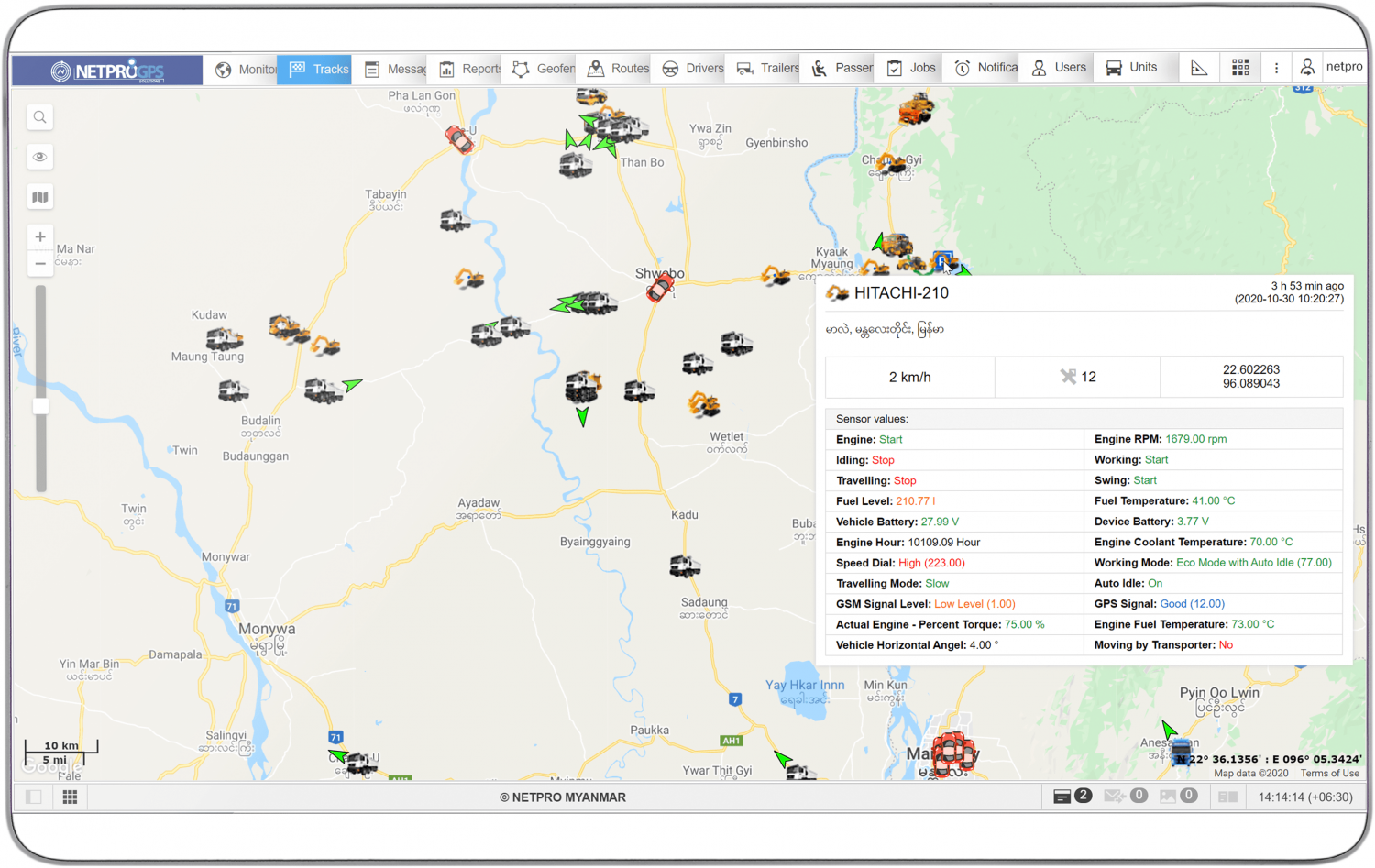

Travelling Hour

Telematics and IoT devices are used to monitor the travelling hours of heavy equipment, in order to better maintain the undercarriage and other parts of the machine. By tracking the travelling hours, companies can ensure regular maintenance is performed and prevent unnecessary wear and tear, leading to a reduction in repair costs and an increase in productivity. Travelling hour monitoring is a tool to help reduce expensive repairing costs and optimize equipment usage.

Idling Hour

Monitoring idling hours of heavy equipment is an important aspect of cost management and maintenance. Idling machines are not generating revenue, but they still consume fuel and wear down on the machine, which ultimately decreases its resale value and increases maintenance costs. By monitoring idling hours and setting thresholds, companies can receive immediate notifications or sound alerts when a machine exceeds the threshold time. This allows operators and owners to take action and minimize unnecessary idling, which can lead to cost savings and improve the overall efficiency of the equipment.

Engine RPM

Monitoring Engine RPM of heavy equipment is an important aspect of performance optimization and fuel efficiency. The RPM parameter can be used to analyze the idling, working and travelling status of the machine. By reducing RPMs to 50% of the maximum value, fuel efficiency can be improved by 15-30%. Our monitoring solution allows for real-time monitoring of acceleration and RPMs, setting of RPM limits, and alarm notifications for fleet managers and operators when limits are exceeded. This allows for more efficient use of the machine and cost savings in fuel consumption.

Engine Coolant Temperature

Monitoring the engine coolant temperature of heavy machinery is essential for preventing major mechanical failures. The engine coolant is responsible for removing excess heat from the internal combustion engine and transferring it to the atmosphere through the radiator, thus maintaining the temperature of the engine. Our monitoring solution allows for real-time monitoring of engine coolant temperature and sends immediate notifications or sound alerts to the operator and owner when the temperature exceeds threshold values. This ensures that the engine is operating within safe temperature ranges and can help prevent costly repairs or downtime.

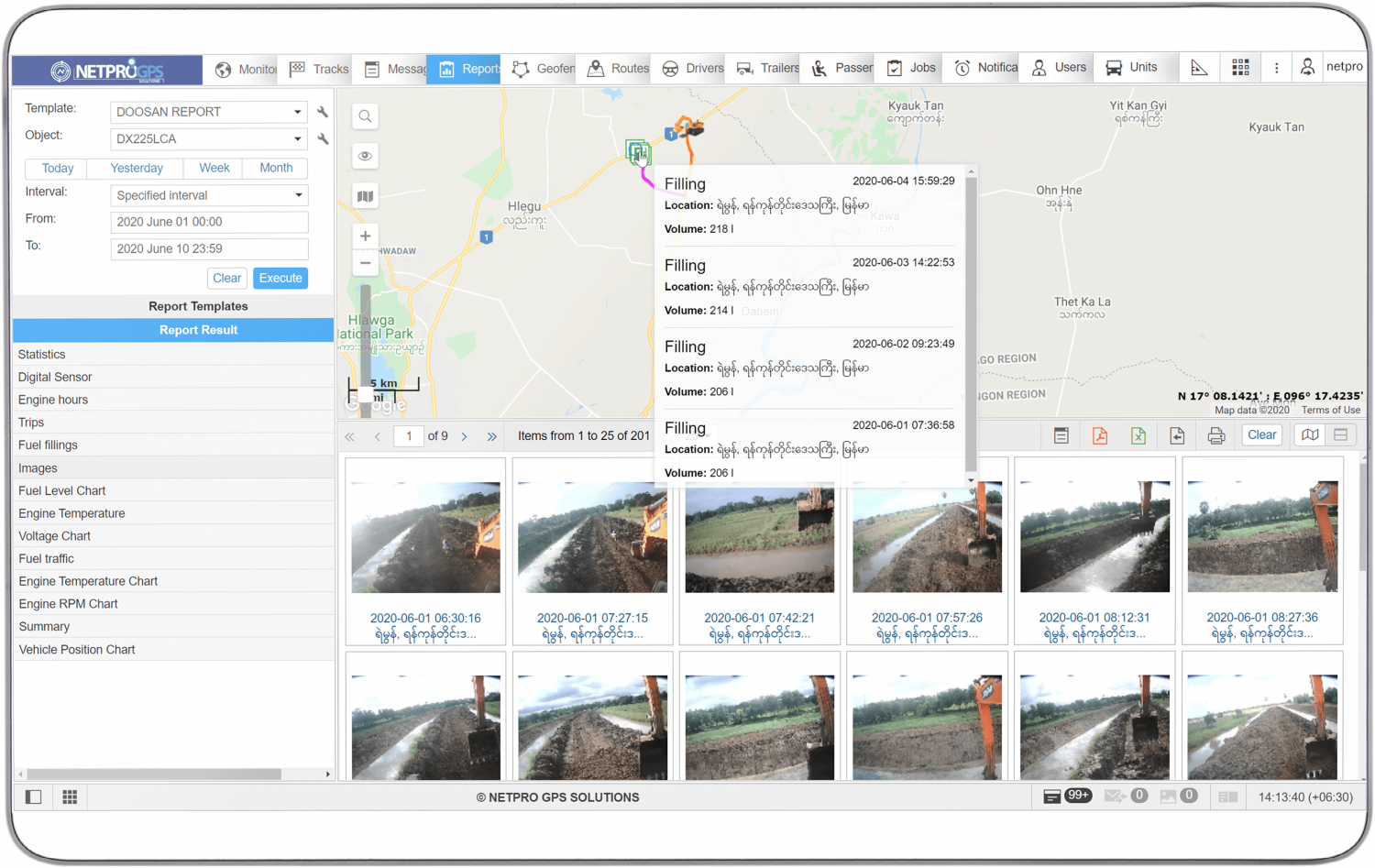

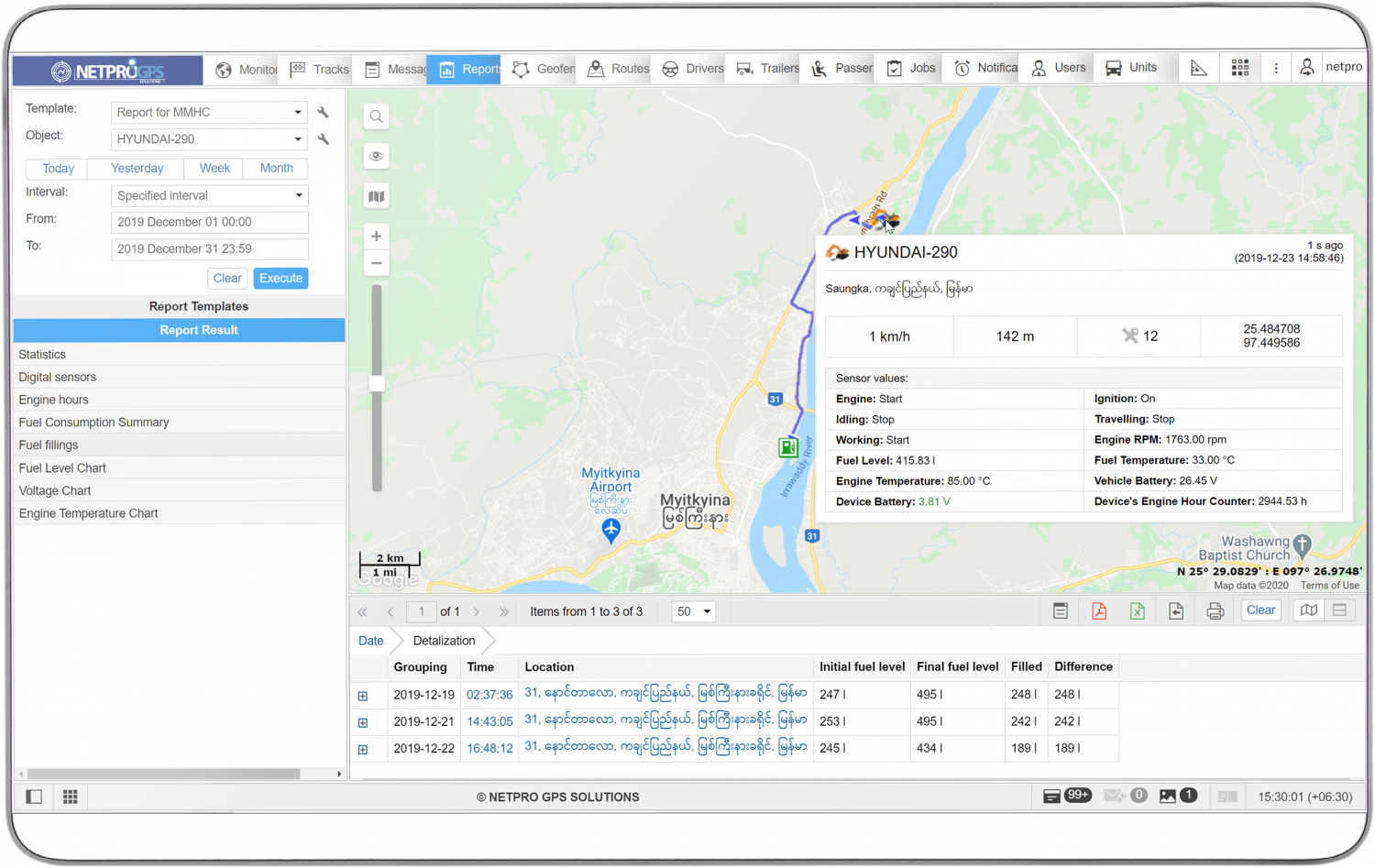

Fuel Consumption

The Fuel consumption monitoring system allows fleet operators or owners to track and control the fuel usage of vehicles, heavy machinery, generators, and ground tanks. It can help to reduce fuel costs, which are often a significant part of total fleet expenses. With our fuel monitoring solution, it is possible to save up to 30% of fleet financial expenses by eliminating fuel misuse and increasing the ROI of your business. The system allows you to identify the actual cost of every single trip and working hour.

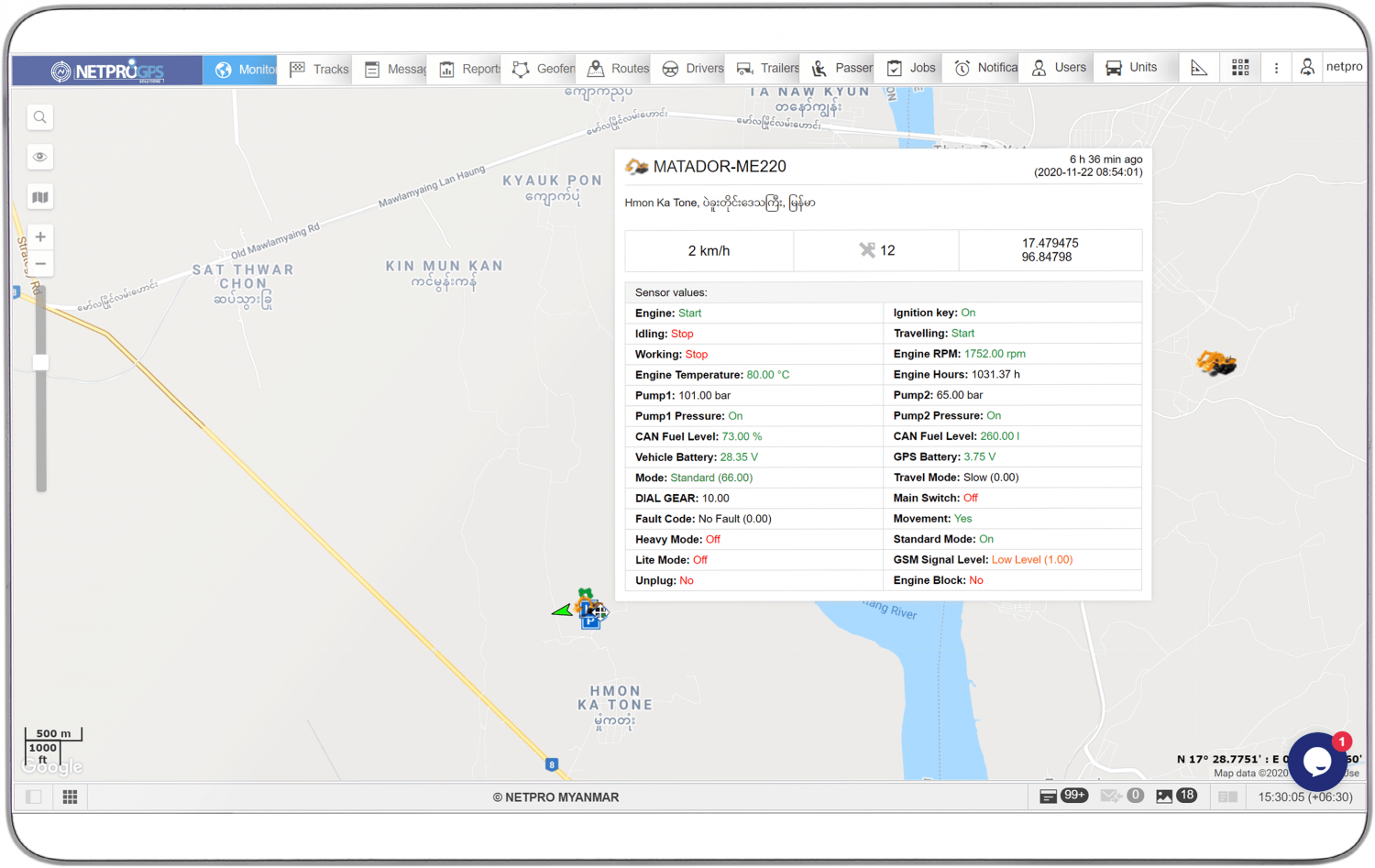

Engine Fault Code

Monitoring engine fault codes is an important aspect of heavy equipment maintenance. Engine is a crucial component of any machine and its performance and productivity are directly linked to it. By using the engine control unit (ECU), which controls multiple sensors and actuators, it is possible to detect and diagnose engine faults before they lead to major breakdowns. These fault codes can be processed and monitored on our platform, allowing companies to take proactive measures to maintain the engine and avoid costly repairs. Additionally, event notifications can be set to receive critical information in real-time, allowing for timely maintenance and repairs to be performed.

Engine Blocking

Engine Blocking is a feature that prevents the engine from starting in certain conditions. It can be used to prevent cheating operators from using machines outside of assigned areas or for personal use. The feature can be controlled by geo-location, time intervals, or manually via SMS commands. It helps to increase security and prevent unauthorized use of the machine. Additionally, it can also be used to reduce fuel consumption and increase the overall productivity of the fleet.